Oiled air filters significantly enhance automotive performance by trapping microscopic particles (2-3 microns) in dusty environments, preventing leaks, and improving airflow in engine intakes. They are especially beneficial for off-road vehicles or those facing high dirt levels. Regular cleaning and replacement are crucial for optimal performance, as clogged intake components can lead to muffler tips issues. In various industries, oiled air filters maintain cleaner air quality, protecting equipment from dust and debris, thereby ensuring worker safety and machine efficiency, making them adaptable and significant across diverse fields.

“Unraveling the mysteries surrounding oiled air filters—a crucial component in various industries. This article aims to clarify common misconceptions and provide an insightful guide. Oiled filters, despite myths, offer unparalleled efficiency in specific applications, notably dust control and industrial settings. We debunk three prevalent myths, highlighting their versatility and optimal usage. Learn about their benefits, from enhanced particle capture to maintenance tips, to determine if oiled air filters are the right choice for your needs.”

- Understanding Oiled Air Filters: The Basics

- – Definition and purpose of oiled air filters

- – Common uses and industries they are employed in

Understanding Oiled Air Filters: The Basics

Oiled air filters are a unique type of automotive filter designed to enhance vehicle performance by improving airflow within the engine’s intake components. Unlike traditional dry filters, these contain a coating or immersing oil that helps trap dust and other contaminants, allowing for smoother air flow. This is especially beneficial in environments with high dirt and debris levels.

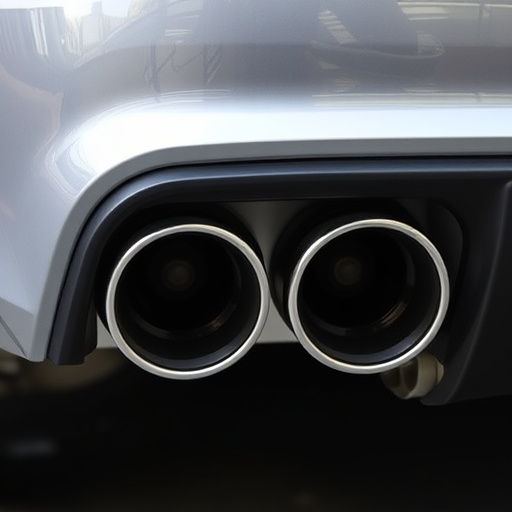

These filters work by allowing clean air to pass through while trapping particles as small as 2-3 microns. The oil acts as a seal around the filter media, preventing leaks that can occur with dry filters. While they may seem like a game-changer for off-road vehicles or those driving in dusty conditions, proper maintenance is crucial. Regular cleaning and replacement are essential to maintain optimal vehicle performance and avoid potential muffler tips issues caused by clogged intake components.

– Definition and purpose of oiled air filters

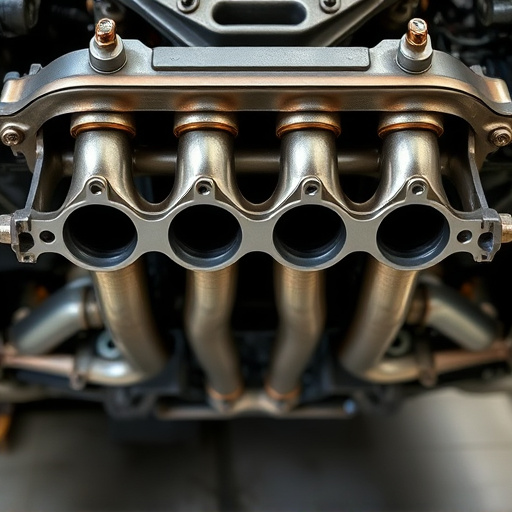

Oiled air filters are designed to enhance the performance of various automotive systems, particularly when it comes to high-performance parts and suspension components. These specialized filters are treated with a fine oil that helps capture microscopic debris, ensuring cleaner air flows through crucial mechanical parts. This process is especially beneficial for cold air intakes, where the intake of cold, clean air is vital for optimal engine performance.

By lubricating the filter media, oiled air filters reduce friction and resistance, allowing for a smoother flow of air. This can lead to improved fuel efficiency and enhanced overall engine health, as it minimizes the strain on critical components. They are a popular choice among car enthusiasts who seek to boost their vehicle’s power and reliability, especially in off-road or high-performance driving conditions.

– Common uses and industries they are employed in

Oiled air filters are versatile tools found in various industries and applications. They are commonly used in automotive settings, particularly for vehicles with high-performance engines or modified cold air intakes (CAIs). These filters are designed to trap fine particles and contaminants, ensuring cleaner and cooler air enters the engine. This is especially beneficial for car owners who want to enhance their vehicle’s performance while maintaining optimal engine temperature.

Beyond automobiles, oiled air filters also have significant uses in industrial settings. Industries such as manufacturing, construction, and even maritime often employ these filters to protect sensitive equipment from dust, debris, and pollutants. In factories, where air quality is critical for worker safety and machine efficiency, oiled air filters are integral components of the ventilation systems. They can be found in various configurations, including high-efficiency particulate air (HEPA) filters, catering to specific needs like removing metal shavings or wood dust from the airstream.

Oiled air filters have gained attention for their unique properties, but it’s essential to separate myth from fact. By understanding their role as efficient particle trappers and recognizing their specific applications, such as in automotive and industrial settings, we can make informed decisions regarding their use. Remember, proper knowledge about oiled air filters empowers us to maintain optimal performance while avoiding potential pitfalls associated with improper usage.