Oiled air filters are a crucial upgrade for vehicle engines, especially with high-performance intake systems, as they efficiently trap contaminants while maintaining optimal airflow through their unique oil-coated mesh. However, this technology has drawbacks; reduced filtration efficiency and slower flow rates can strain exhaust components and intake parts may suffer from oil buildup. Regular maintenance is essential to balance lubrication levels for peak engine performance, longevity, and overall health.

“Uncover the intriguing world of oiled air filters and their unique performance dynamics. This comprehensive guide explores the effects of oil content on air filter efficiency, flow rates, and lifespan. From understanding the fundamental principles of oiled air filters to selecting the optimal oiling level for specific applications, we delve into the practicalities. Discover how the right balance of oil can enhance or hinder airflow, impacting various systems’ performance. By the end, readers will be equipped with insights to make informed decisions regarding this specialized filtration method.”

- Understanding Oiled Air Filters: How They Work and Their Basic Properties

- Performance Impact of Oil Content: Efficiency, Flow Rate, and Filter Life

- Practical Considerations: Choosing the Right Oiling Level for Your Application

Understanding Oiled Air Filters: How They Work and Their Basic Properties

Air filters are a critical component of any vehicle’s engine performance and efficiency. Oiled air filters, in particular, have gained popularity due to their unique design and benefits. These filters use a fine mesh material that is coated with a thin layer of oil, which allows for efficient trapping of dust, dirt, and other contaminants while ensuring optimal airflow. The oiled coating creates a smooth, fluid path for air molecules, enhancing the overall performance of the engine.

Unlike dry or cotton air filters, oiled air filters are designed to be used with high-performance air intake systems, such as cold air intakes, which draw cool and dense air directly from outside the vehicle. The oil in these filters acts as a lubricant, reducing friction and allowing for smoother passage of air. This is especially beneficial when combined with a cat-back exhaust system, where efficient airflow is crucial for optimal engine power and torque delivery. By understanding how oiled air filters work, drivers can make informed decisions regarding their vehicle’s air intake systems, ensuring maximum performance and longevity.

Performance Impact of Oil Content: Efficiency, Flow Rate, and Filter Life

The amount of oil in an air filter has a notable impact on its performance and longevity. When introducing oil into an air filter, it significantly influences several key factors. Efficiency is one such area; oiled filters tend to have lower efficiency as the oil can obstruct airflow, leading to reduced filtration effectiveness. This effect is particularly noticeable in high-flow applications, where even a small decrease in efficiency can result in substantial performance losses.

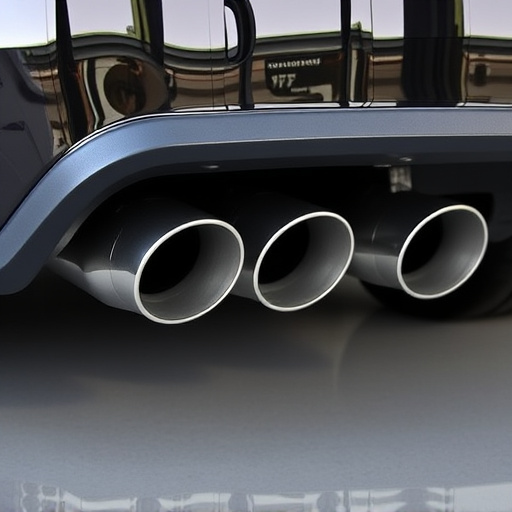

Moreover, the presence of oil affects flow rate, slowing it down compared to dry filters. This reduction in flow rate not only impacts engine performance but also increases backpressure in the system, which can lead to increased strain on other components like exhaust mufflers and brake pads. Intake components, too, may suffer from reduced efficiency due to oil buildup, compromising overall engine health. Additionally, oiled filters require more frequent replacement as the oil accumulation shortens their lifespan, putting a greater emphasis on regular maintenance for optimal system functionality.

Practical Considerations: Choosing the Right Oiling Level for Your Application

When considering the performance differences between light and heavy oiling, it’s crucial to understand that the right amount of lubrication can significantly impact your application’s efficiency. For instance, an oiled air filter in a vehicle’s engine may require a specific oiling level to ensure optimal airflow and prevent contamination. Too little oiling can lead to increased friction and wear on sensitive parts, while excessive oiling might cause inefficient airflow, reducing overall performance.

Choosing the appropriate oiling level depends on several factors, including the nature of the application, environmental conditions, and the materials used in critical components like exhaust tips, brake components, or performance exhaust systems. For automotive applications, regular maintenance and monitoring of oil levels are essential to ensure peak engine performance and longevity. This practical consideration is vital for maintaining a balance between fluidity and efficiency, ultimately influencing the overall health and output of your system.

In conclusion, oiled air filters offer distinct advantages in terms of efficiency, flow rate, and longevity, but the optimal oil content depends on specific application requirements. By understanding the performance differences between light and heavy oiling, users can select the right level for their needs, ensuring top-notch filtration without compromise. This knowledge is crucial for maintaining efficient and cost-effective air quality in diverse industries.